Tank Heaters

The innovative fin-tube design of BROWN FINTUBE® products from Metalforms Heat Transfer revolutionized the industry and has been providing field-proven performance ever since. As one of the most trusted heat transfer brands in the industry, BROWN FINTUBE® Products allow you to maintain or increase your tank temperature more efficiently, at a fraction of the cost. Learn more about how our tank heating solutions could benefit your operation.

CONTACT US

Call us today to speak with one of our heat transfer specialists: (+1) 713.466.3535 or click to contact us below:

After-Hours Parts Support

inquiry@metalformsht.com

Product Portfolio

BROWN FINTUBE® tank heating products typically use steam or hot oil. They are engineered to fit most applications either together or individually. Choose from solid or perforated designs, and various metals (C.S., S.S., nickel, etc.). If standard materials, styles, or sizes do not meet your requirements, we can customize our products.

Horizontal Tank Heater (Internal)

Vertical Tank Heater (Internal)

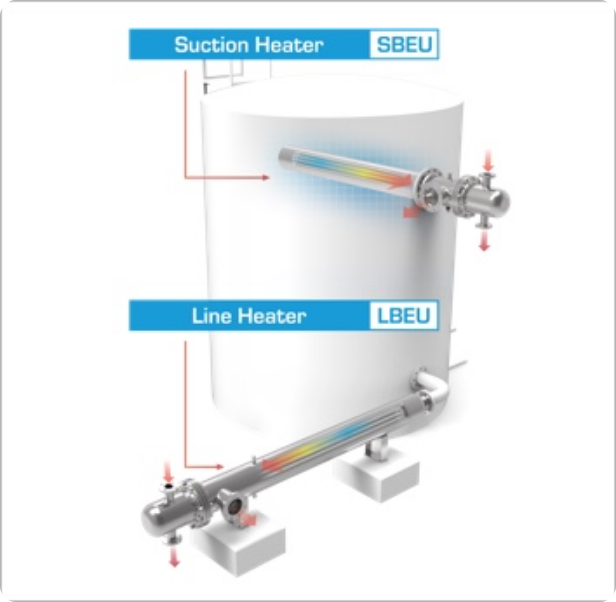

Suction Heater & Line Heater (Intermittent)

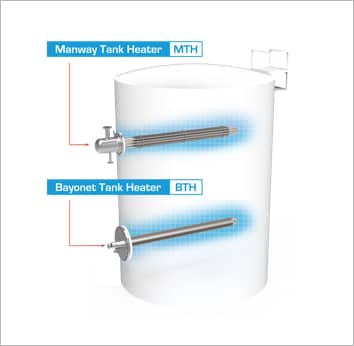

Manway Tank Heater & Bayonet Tank Heater (Stab-In)

Benefits

Ease of Maintenance, Inspection & Cleaning

The small footprint allows for more access to tank floor for inspections.

In the case of removing the heating elements, BROWN FINTUBE® tank heaters are more easily removed and replaced.

Fouling Mitigation

The convective currents created by the heaters in the tank help keep more particles suspended in the fluid, rather than settling.

Lower Capital Cost

Extended fin surface is less expensive than equivalent bare surface.

Lighter weight and smaller size requires less support.

Easy installation and less field welding than bare coils.

Reduced Heating Costs

BROWN FINTUBE® finned tank heating coils can reduce the fuel cost associated with heating systems.

Combining multiple heater types can result in a more efficient heating process, ultimately saving money.

Common Applications

- Sulfur melting

- Molten sulfur

- Asphalt

- Crude oil

- Fuel oil

- Lube oil

…and much more

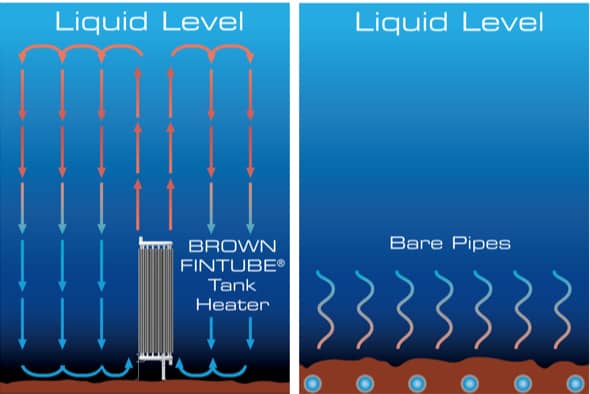

Thermo-siphon Effect

Compared to bare pipes, BROWN FINTUBE® tank heaters induce stronger thermal currents in the tank. Product next to the fintube rapidly heats and rises due to its lowered specific gravity, creating a thermal siphon effect. This contributes to a higher rate of heat transfer. Sedimentation is minimized as the tank contents are agitated and particles remain in suspension. As a result, heating surfaces tend to be self-cleaning, and sludge is reduced.

Features

Compact Design

The use of extended fin surfaces provides up to 12x the surface area of a bare pipe equivalent. This allows for more surface area in a smaller package.

Fewer Field Welds

Each heater requires approximately two field welds, which is much less than conventional bare pipe. This results in reduced risk of leaking, and less time and cost for inspections.

Lower Skin Temperature

The extended fin surface provides a lower metal skin temperature in contact with process fluid. This can reduce the heat-related fouling rate.

Closures

Internal

HL / HEL (Horizontal Heating Coil)

Perforated longitudinal fins or Helical fins based on application.

Designed for use with steam as heating medium Sloped for proper condensate drainage.

HL-S / HEL-S (Horizontal Heating Coil)

Perforated longitudinal fins or Helical fins based on application.

Designed for use with hot liquid as heating medium.

TF (Vertical Heating Coil)

Can be installed from roof Thermosiphon effect.

Stab-In

.jpg)

BTH (Bayonet Tank Heater)

Designed for use with steam.

Mounts directly to tank

MTH (Manway Tank Heater)

Designed for use with steam or hot liquid.

Mounts directly to tank.

Intermittent

LBEU (Line Heater)

External to tank.

Ideal for multiple tanks with the same fluid for consolidated heating.

SBEU (Suction Heater)

Mounted directly to tank.

Allows fluid to be heated as it exits tank.